Injection blow moulding

Used for production of most PET and RPET plastic bottles

Eco-design is a central concern for us, so we view our recent acquisition of 36 fully electric injection

moulding machines as an opportunity for us to develop greener energy sources.

We are the only company in France with such a large fleet of machines, enabling us to offer greener and

more sustainable products.

Fully electric operation means green energy, no more hydraulics, no water pollution and the lowest

consumption on the market.

At the same time, we are reinforcing our green approach by replacing all our dryers with

ultra-low-consumption models.

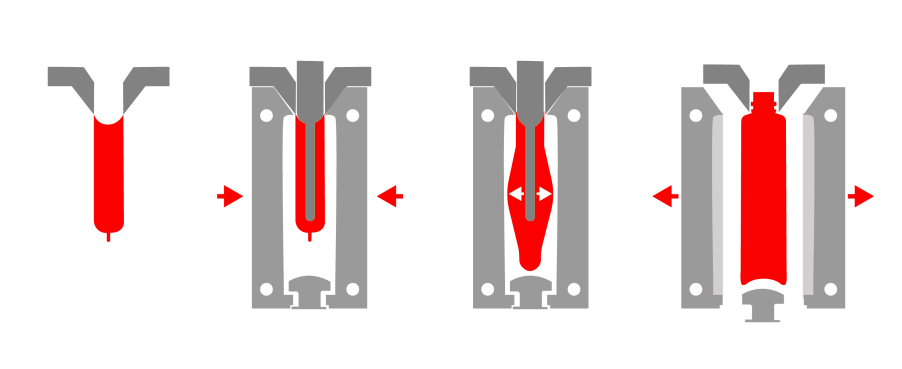

Plastic extrusion blow moulding is a process used to manufacture hollow plastic objects.

- A hot plastic tube is cut in two and a cold mould is positioned around it.

- Air is injected into the tube so that the plastic material is forced against the internal surfaces of the mould.

- The mould is then cooled rapidly so that the tube, which has now become a plastic packaging product, can be removed.

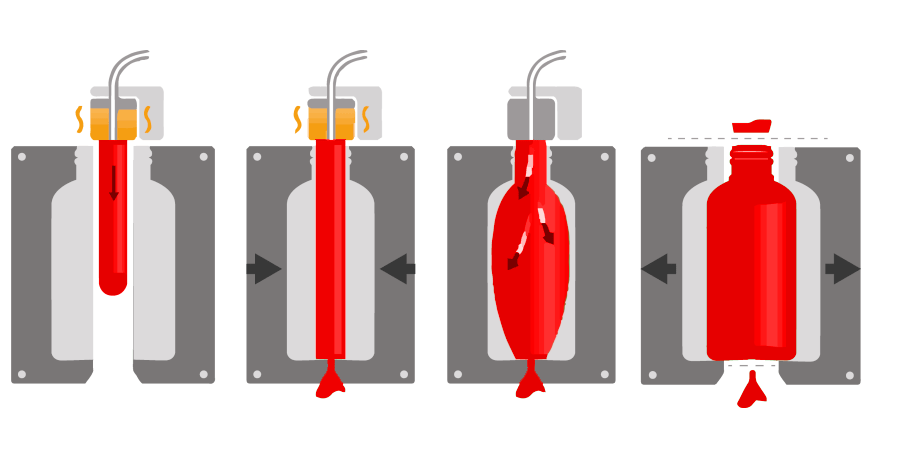

Plastic injection blow moulding is a process used to manufacture most plastic bottles.

- The preformed plastic is heated.

- A rod stretches the preformed plastic to the bottom of the mould.

- A powerful jet of air pushes the material against the interior of the mould. The preform thus takes shape and the mould is cooled and then opened.

- The mould is then cooled so that the preform, which has now become a plastic bottle, can be removed.

To change the shape of the bottle, we just change the mould.